100% Original Low Temperature Silicone Curing Agent - Silicone O-ring Adhesive Of Fast Bonding At High Temperature – Tosichen

100% Original Low Temperature Silicone Curing Agent - Silicone O-ring Adhesive Of Fast Bonding At High Temperature – Tosichen Detail:

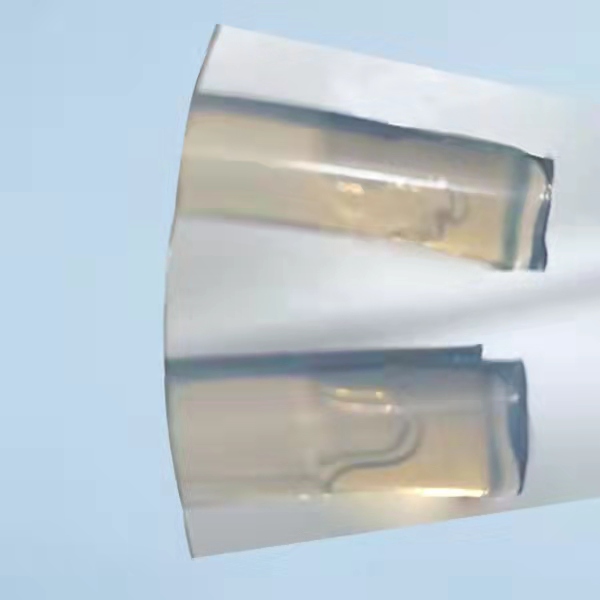

Silicone O-ring Adhesive Of Fast Bonding At High Temperature

TS-85AB

PRODUCT DESCRIPTION

TS-85AB is two components of silicone adhesive, applied to cured silicone rubber bond cured silicone rubber at high temperature .The silicone adhesive is characterized with fast curing ,strong bonding strength,waterproof and good elasticity.It is mainly used for the adhesion between silicone O-ring, silicone gasket, silicone rubber sealing strip , silicone tube, silicone special shaped strip and silicone foam board . The curing time of TS-85AB is very short by high temperature heating, so the silicone adhesive curing speed is fast and high productivity of bonding silicone.

TECHNICAL PARAMETER

Appearance: transparent paste

Density ( g/cm³): 1.0~1.1

USAGE METHOD 1

1, TS-85A mix TS-85B evenly by weight ratio A:B=1:1

2, Coating the mixed TS-85AB on silicone surface to be bonded

3, The two silicone surfaces are pressed together with a fixture

4, Heating at temperature 180°C for 10~15 seconds by oven

(The actual heat curing time can be micro adjustment in production according to the size of the

silicone product)

USAGE METHOD 2

1, Silicone O-ring bonding needs to be bonded by heating bonding machine

2,TS-85A mix TS-85B evenly by weight ratio A:B=1:1

3,Coating silicone adhesive TS-85AB method: Scrape a small amount of mixed TS-85AB onto a flat surface ((such as:steel plate,acrylic plate),scrape the TS-85AB flat with a knife(maintain a certain adhesive thickness).Press one end of the silicone strip on the flat adhesive to adhere a layer of adhesive on the silicone strip’s end, then put in the fixed mold with good temperature and press two ends of the silicone strip together forcefully by hands. Let hands go after the upper mold is closed.

4,The temperature of the fixed mold is 180°C, the curing time is 10~15 seconds. The actual heat curing time can be micro adjustment in production according to the size of the O-rings.

You can watch the bonding silicone O-ring process by heating bonding machine at the Website https://www.youtube.com/shorts/KjABczYGcwo

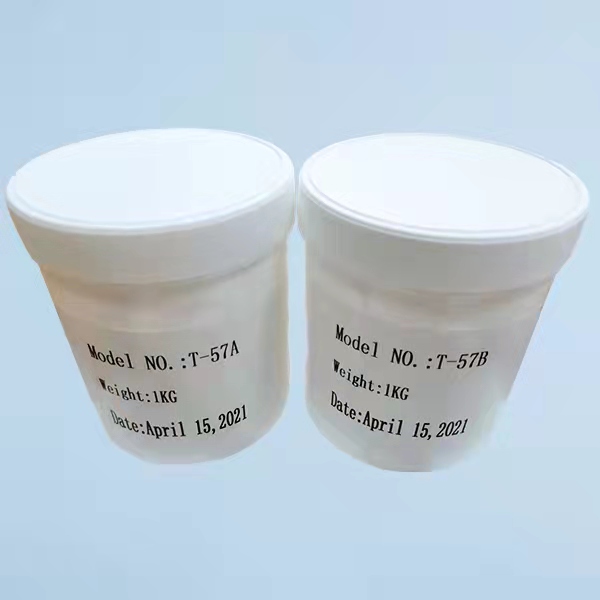

PACKING

1KG/Bottle

SHELF LIFE

6 months without mixing

SAMPLE

Free samples

ATTENTION

1,The mixed silicone adhesive should be used up within 4 hours after TS-85A mixing TS-85B . If it is more than 4 hours, it is necessary to check the mixed adhesive by yourself. If it is found that there is mixed adhesive curing phenomenon, please replace with new silicone adhesive TS-85AB.

2, Store TS-85AB in dry and cool place, away from heat source and open flame.

REMARKS

If bonding silicone O-ring, silicone gasket or silicone rubber at room temperature, please use our RTV silicone adhesive TS-673.

Product detail pictures:

Related Product Guide:

We consistently execute our spirit of ''Innovation bringing progress, Highly-quality ensuring subsistence, Administration advertising and marketing gain, Credit history attracting buyers for 100% Original Low Temperature Silicone Curing Agent - Silicone O-ring Adhesive Of Fast Bonding At High Temperature – Tosichen , The product will supply to all over the world, such as: Italy, India, Turkey, Besides there are also professional production and management , advanced production equipment to assure our quality and delivery time , our company pursues the principle of good faith, high-quality and high-efficiency. We guarantee that our company will try our best to reduce customer purchase cost, shorten the period of purchase, stable products quality, increase customers' satisfaction and achieve win-win situation .

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!